Air-Operated, Normally Closed ValvesSeries BST-NC • heavy-duty 2-way, spring-return globe style valves for corrosive & ultra-pure liquidsFormerly Series EST-NC

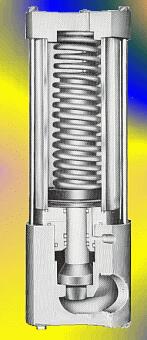

Photo at right is Series BST-NC, 3/4" through 2" pipe sizes. Below left is Series BST-NC, which is the 1/2" version. Plast-O-Matic Series BST-NC globe-pattern air operated normally closed valves are ideal for handling pureliquids, chemicals, acids, and caustics where high flow and visual verification are important. Features:- PTFE shaft for non-sticking operation.

- Clear acrylic cylinder for visual verification of valve position.

- Fail-Dry® safety feature.

- 1,000,000 cycle design,

- Low pressure drop with high flow rates; pressure or vacuum service.

- Bubble-tight sealing.

- Spring & fasteners not in contact with liquid.

- Manual set throttling limit stop available.

Click here for video presentation of these advantages. Click here for video presentation of these advantages.

Left Click to Play, Right Click to Download

OperationThe valve disk or main seal is held closed against the main orifice via spring force. This spring will automatically close against line pressure up to 100 PSI (125 PSI on 1/2" size). Standard shop air or hydraulic power is used to compress the spring and open the valve. Valves require a 3-way air solenoid valve to control the air or hydraulic pressure used to open the valve. It is recommended to regulate the air pressure to 60 - 80 PSI. The air should be filtered and lubricated for longer valve life.

In situations where air pressure is not available, water pressure can be used so long as the pressure available is sufficient to actuate the valve. If hydraulic media is not clean, a filter should be used. Valves should be mounted upright for best results and less strain on piping. Flow direction is indicated and should be adhered to for best results. The Fail-Dry safety feature is a patented Plast-O-Matic design whereby the liquid seals and air pressure seals are separated by a vent, which will give indication of a valve problem before a system shutdown is necessary. For a complete explanation of the Fail-Dry system, please click here. Sizes & MaterialsSeries BST-NC is available in 1/2", 3/4", 1", 1¼", 1½" and 2" pipe sizes. Valve body is Geon® PVC. Cylinder walls are high-strength acrylic. Shaft is PTFE. External fasteners are stainless steel. Spring is steel. Elastomeric seals are choice of Viton®, EPDM, or Buna-nitrile. For other materials, please contact the Plast-O-Matic Technical Department at 973-256-3000 or e-mail info@plastomatic.com Connections, Pressure RatingsStandard connections are NPT. Optional connections are socket or flanged. Air inlet connection is 1/8" NPT. Maximum air pressure is 100 PSI. Minimum air pressure required to open the valve is 45 PSI (50 PSI for 3/4", 30 PSI for 1/2"). Use of an air flow rate valve may be required to prevent water hammer, depending on the application. Maximum liquid line pressure is 100 PSI, except for 1/2" BST-NC, which is 125 PSI.

Photo shows Series BST in an extremely harsh environment. Notice that despite the splattering acid, the valves are completely unaffected. Design:Series BST-NC automatic valves require air or hydraulic pressure to open and are normally closed with a spring. The spring is not in the liquid. In Series BST-NC, three o-rings seal against a pressure balanced PTFE shaft; in 1/2" sizes, five u-cups seal against a pressure balanced PTFE shaft. This, in conjunction with a poppet seat at the valve orifice, results in a non-sticking design. Throttling Option:A very simple and inexpensive throttling limit stop to control flow is available for BST-NC. This is adjusted in the field to a set opening and the valve will always re-open to that point. If the line pressure remains constant, the flow will then remain constant. Series BST-NC Dimensions:Please note that dimensions for 1/2" sizes shown here do not use the same letter references as the printed catalog or .pdf file.  | Size | 1/2" | 3/4" | 1" | 1¼" | 1½" | 2" | | DIM | IN | MM | IN. | MM | IN. | MM | IN | MM | IN. | MM | IN. | MM | | A | 2 3/8 | 60.3 | 3 1/2 | 88.9 | 3 3/4 | 95.3 | 4 9/16 | 115.9 | 5 | 127.0 | 6 | 152.4 | | B | 1 3/4 | 44.5 | 1 3/4 | 44.5 | 1 3/4 | 44.5 | 1 5/8 | 41.3 | 1 3/4 | 44.5 | 2 3/8 | 60.3 | | C | 6 1/2 | 165.1 | 9 3/8 | 238.0 | 11 5/16 | 287.3 | 13 | 330.2 | 15 | 381.0 | 15 13/16 | 401.6 | | D | 1 3/8 | 34.9 | 1 5/32 | 29.2 | 1 3/8 | 34.8 | 1 25/32 | 45.2 | 1 25/32 | 45.2 | 1 15/32 | 37.1 | | E | . | . | 1 15/16 | 49.2 | 2 1/8 | 54.0 | 2 5/16 | 50.8 | 2 1/2 | 63.5 | 3 | 76.2 | | F | 2 3/8 | 60.3 | 3 | 76.2 | 4 | 101.6 | 4 1/2 | 114.3 | 6 | 152.4 | 7 | 177.8 | | G | . | . | 4 | 101.6 | 5 | 127.0 | 5 3/4 | 146.1 | 7 3/8 | 187.2 | 8 1/2 | 215.9 |

Point of clarification: The "D" dimension indicates distance from center of piping connection to bottom of valve. The "E" height indicates distance from center of piping connection to bottom of optional flange. The "G" dimension indicates length with optional flanges. The "B" dimension is a "maximum" dimension. Specifications & Ordering Information:| Pipe Size | Cv Factor | Pressure Ratings | Model Numbers | | | | Minimum Air to Open | Maximum Liquid Line Pressure | | | 1/2" | 3.6 | 30 PSI

2,06 BAR | 125 PSI

8,6 BAR | BST050V-NC-PV (Viton Seals)

BST050EP-NC-PV (EPDM Seals) | | 3/4" | 8.5 | 50 PSI

3,45 BAR | 100 PSI

6,9 BAR | BST075V-NC-PV (Viton Seals)

BST075EP-NC-PV (EPDM Seals) | | 1" | 15.0 | 45 PSI

3,11 BAR | 100 PSI

6,9 BAR | BST100V-NC-PV (Viton Seals)

BST100EP-NC-PV (EPDM Seals) | | 1¼" | 24.0 | 45 PSI

3,11 BAR | 100 PSI

6,9 BAR | BST125V-NC-PV (Viton Seals)

BST125EP-NC-PV (EPDM Seals) | | 1½" | 33.0 | 45 PSI

3,11 BAR | 100 PSI

6,9 BAR | BST150V-NC-PV (Viton Seals)

BST150EP-NC-PV (EPDM Seals) | | 2" | 60.0 | 45 PSI

3,11 BAR | 100 PSI

6,9 BAR | BST200V-NC-PV (Viton Seals)

BST200EP-NC-PV (EPDM Seals) | To order with throttling limit stops, add "LS" to part number, after the "NC". Example: BST075V-NC-LS-PV.

For Buna-nitrile seals, replace "V" or "EP" with "B". Example: BST075B-NC-PV

Maximum air pressure rating is 100 PSI/6,90 BAR

No minimum liquid process pressure is required for the valve to open or close. |

Helpful Links:.PDF file of Catalog ASO This catalog provides complete data and sample specifications for Globe Style Air Shut-off & Diverter Valves Series BAT, BLT, BST-NC, BST-NO, F, BFS. Series BST Normally-Open designs similar in size and appearance, except the valve is fail-safe to open rather than close. Series BLT line-acting design similar in size and appearance, except the valve require air or hydraulic power to close and uses liquid line pressure to open. Series BAT double-acting design similar in size and appearance, except the valve require air or hydraulic power to open and close; no minimum line pressure requirement. Series BSD & BSDA Air-actuated shutoff valves for pressure and drain applications. Index Page to all Air-Actuated Globe style Valves with a brief description of each. Includes compact valves, diverter valves, valves that use line pressure to open, double-acting valves, and more. This may be the page you used to arrive here. Online video Plast-O-Matic's Tech Sales Manager Andy Ryan explains the advantages of Series BST in this brief video.

|