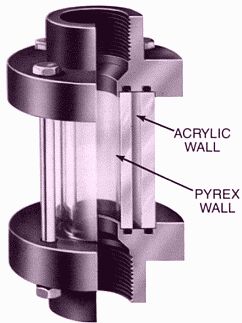

Series GY Double Wall Sight Flow Glasses

Advantages of Series GY Sight Glasses:- Double-wall construction featuring Pyrex® inner wall

- Large 360° viewing area.

- Full flow design (no corners to collect debris).

- Wide choice of select plastic materials to assure maximum chemical compatibility.

- Little or no maintenance required.

- No special hardware required for installation (completely assembled and pre-tested).

Design FeaturesTrue Blue® Series GY flow indicators are designed to indicate the presence or clarity of high purity or corrosive liquid in a piping system. For use with ultrapure liquids or chemicals compatible with acrylic. O-ring seals are used on Series GY indicators allowing them to seal at extremely low pressures as well as high pressures. GY flow indicators are full ported, eliminating any possible flow resistance. Pipe sizes are 1/2" through 3" NPT. BSP sizes also available. Optional fluttering streamers are available. Materials of Construction Ends on Series "GY" indicators are Geon® PVC and Polypropylene. Standard O-ring seals are either EPDM or Viton®; Buna-nitrile is optional. Standard fasteners are stainless steel. The transparent outer cylinder wall is high impact strength acrylic. The inner wall (wetted) is Pyrex (CAUTION: cannot be used with hydrofluoric acid or sodium hydroxide which will etch the glass). Optional fluttering streamers are corrosion resistant thermoplastic. Pressure & Temperature ChartsSeries GY with Geon® PVC Ends

Series GY with Polypropylene Ends[All threaded connections on Series GY are concentrically machined and designed to handle working pressures up to 50 PSI (3,5 Bar) at 185ºF (85ºC) as well as full vacuum. These connections, however, could leak at almost any pressure due to the unstable nature of the virgin polypropylene under pressure. If such a leak should occur, the threaded connection should be properly fillet welded. Generally speaking, these leak problems are almost non-existent with vacuum applications or pressure under 15 PSI.]

Series GY with Kynar® PVDF Ends (1-1/2 - 3" shown)

Series GY with PTFE Ends

DimensionsOrdering Information| Pipe Size (NPT or BSP) | Part # w/PVC Ends & EPDM Seals | Part # w/PVC Ends & Viton Seals | 1/2"

3/4"

1"

1-1/4"

1-1/2"

2"

3"

| GY050EP-PV

GY075EP-PV

GY100EP-PV

GY125EP-PV

GY150EP-PV

GY200EP-PV

GY300EP-PV

| GY050V-PV

GY075V-PV

GY100V-PV

GY125V-PV

GY150V-PV

GY200V-PV

GY300V-PV

| If Buna-N seals are required, change EP in part number to B; for example: GY050B-PV. If fluttering streamers are required, conclude part number with -S; for example: GY050EP-PV-S. If natural polypropylene ends are required, change -PV to -PP; for example: GY050V-PP. For Kynar PVDF, change -PV to -PF. For PTFE, change -PV to -TF. NPT threads will be supplied unless BSP threads are specified. |

Operation & UseWhen properly installed, Plast-O-Matic flow and level indicators are automatic in operation and require little or no attention. These flow indicators will easily show the flow of turbulent liquids without assistance from fluttering devices. With clear or opaque liquids that are not turbulent and do not contain entrained air bubbles, the flow may be difficult to see. In this case a Plast-O-Matic fluttering device within the cylinder will indicate movement of the liquid. Installation ConsiderationsAll Plast-O-Matic flow and level indicators are easily installed in a piping system. The flow indicators may be installed either vertically or horizontally; however, the level indicators can only be installed vertically. Series "GY" flow indicators are simply threaded into a piping system. They should only be connected to plastic fittings. Male threads should be wrapped with PTFE tape or other acceptable pipe sealant and only made hand-tight, followed by a one-quarter turn more using a strap wrench. Greater forces tend to stretch or distort the plastic material which could lead to future rupture. Do not use pipe wrenches, locking channel pliers or vise-lock pliers; all of these create stress in the molecular structure of the plastic. Do not connect to a metal pipe. This could cut into the plastic and also cause a future rupture. Although these flow indicators have no specific inlet or outlet, care should be exercised when installing such units that have streamers for fluttering devices. They must be installed in such a manner that the fluid flow will force the streamers into the indicator's viewing area. Cylinder Wall InformationClearly, any flow or level indicator is only as good as the quality of its cylinder wall(s) since this is where the viewing takes place. The transparent cylinder walls used in PLAST-O-MATIC flow and level indicators are chosen for characteristics such as high corrosion resistance, high impact strength, and high light transmission. The inner transparent cylinder walls used in the Series "GY" are Pyrex, a borosilicate glass of very low alkali content that resists attack from most bases and acids with the exception of hydrofluoric acid and sodium hydroxide. This is the same material used in manufacturing glass pipe that is extensively used in the chemical, food, beverage and pharmaceutical industries. The outer transparent cylinder walls are manufactured of a high impact strength acrylic. This material possesses uniform optical quality and has an extremely high light transmission factor, which is of great importance when the color or clarity of your liquid is a prime consideration. Acrylic cylinder walls are ultra-violet resistant. Fluttering DevicesAll PLAST-O-MATIC flow indicators can be used to indicate the presence of liquid flow when the liquid lends itself to turbulence or has entrained air bubbles that make viewing effortless. When the liquid is either clear or opaque a mechanical device is required to identify liquid movement. In such applications the use of PLAST-O-MATIC optional fluttering devices is a necessity. Optional vinyl streamers that flutter in the presence of flow are available for Series "GX" flow indicators. Modified & Custom Sight GlassesAs specialists in thermoplastic sight glass design for over 30 years, Plast-O-Matic's engineering department can modify Series GY...or create an all-new product for any special application. Depending on complexity, minimum quantities and/or design fees may apply. Please contact our Technical Sales Group at (973) 256-3000 for details.

Links to Web Pages with Specifications for each type of Sight GlassPlease click here for web page specific to Series GX Single cylinder wall flow indicators Please click here for web page specific to Series GYW Double-Wall, Wafer Style Sight Glasses Please click here for web page specific to Series GL Double Cylinder Wall, Pyrex & Acrylic Level Indicators

Links to PDF filesPlease note that the above web pages are slightly more up-to-date than the .pdf files below, and the charts may print more clearly in the web pages. We suggest you try the above .html format, unless you need the convenience of "forwarding" .pdf files, etc. Thank you. Please Click here for dimensional specifications, pressure & temperature ratings for all Sight Glasses & Level Indicators PDF format Please click here for PDF file specific to Series GX Single cylinder wall flow indicators Please click here for PDF file specific to Series GY Double cylinder wall flow indicators Please click here for PDF file specific to Series GYW Double-Wall, Wafer Style Sight Glasses Please click here for PDF file specific to Series GL Double Cylinder Wall, Pyrex & Acrylic Level Indicators |