Introduction to Check Valves

True Blue® PVC, CPVC, PVDF, PP & PT FE thermoplastic Check Valves help you stop unwanted reverse flow with an automatic bubble-tight seal.

FE thermoplastic Check Valves help you stop unwanted reverse flow with an automatic bubble-tight seal.

• Series CKM & CK Diaphragm operated; self-sealing and normally-closed.

• Series CKS PFA encapsulated spring designs; self-sealing and normally-closed.

• Series CKD Compact design for low pressure applications; not self-sealing but has lower cracking pressure.

All True Blue Check Valves feature rugged thermoplastic construction with no wetted metal parts. As your assurance of quality, each valve is individually tested under pressure by a Plast-O-Matic inspector prior to shipment.

Function of a Check Valve

According to Ryan Driscoll, Inside Sales Engineer at ValveMan.com, “check valves are unidirectional valves that are installed in piping systems to prevent the backflow of water or pressure surge. These problems are prevented by the check valve’s self controlling ability, which ensures that the water flows in one direction.” Driscoll explains that the benefits include mitigation of water hammer, and improved pipe and pump longevity.

Diaphragm Check Valves are Superior to “ball checks”

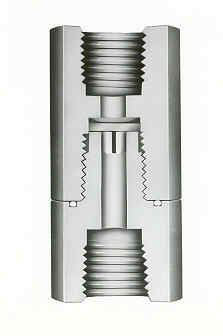

The patented diaphragm in the Plast-O-Matic True Blue Check Valve is designed to re-seat with a bubble tight seal regardless of mounting position or reverse flow. Ball style check valves require two properties to seal properly: First, the ball check must be mounted with the flow direction pointed up, because gravity is required to pull the ball to the seat. Secondly, some reverse pressure and flow must be present, because pressure is required to seal the ball exactly on the seat.

If either of these conditions are not met, the ball check will leak! On the other hand, the Plast-O-Matic diaphragm check will seal in any position, whether or not flow is present.

Here’s a Simple Test: Take a Plast-O-Matic diaphragm check valve and place it flow arrow up on a paper towel. Pour a small amount of water into the outlet, lift up the valve, and you will see that it has remained absolutely sealed — no evidence of dampness on the paper towel. Now take any ball-style check valve and perform the exact same test — just be sure to have extra paper towels on hand!

![]() Compare ball checks to our patented diaphragm check!

Compare ball checks to our patented diaphragm check!

|

Series CKM: Unsurpassed performance in a plastic check valve. Patented diaphragm design provides the ultimate normally-closed, zero reverse-flow valve. Available pipe sizes 1/2″ 3/4″ and 1″. Body materials are Geon® PVC, Corzan® CPVC, Glass-filled polypropylene, and Kynar® PVDF. Seal materials are EPDM and FKM. • Self-sealing — not dependent upon gravity, mounting position or reverse flow. Please click here for complete specifications (a web page specific to Series CKM) |

|

Series CK: Unsurpassed performance in a plastic check valve. Patented diaphragm design provides the ultimate normally-closed, zero reverse-flow valve. Available pipe sizes 3/4″ and 1″. PTFE Body; seal materials are EPDM and FKM. • Self-sealing — not dependent upon gravity, mounting position or reverse flow. Please click here for complete specifications (a web page specific to Series CK & CKM) |

|

Unsurpassed performance in a plastic check valve. Unique poppet and PFA encapsulated spring design emulates the CKM diaphragm and provides the ultimate normally-closed, zero reverse-flow valve. Available pipe sizes 1-1/2″ 2″ and 3″. Body materials are Geon PVC, Corzan CPVC, Natural polypropylene, and Kynar PVDF. Seal materials are EPDM and FKM (Viton). • Self-sealing — not dependent upon gravity, mounting position or reverse flow. |

|

Series CKD: These 1/4″ & 1/2″ valves utilize a flexible elastomer disk as opposed to Plast-O-Matic’s patented diaphragm. The advantage is that the CKD requires even less pressure than the CKM to open.

Also note that in 1/2″ piping systems where high flow is required, the 1/2″ Series CKM check valve should be used, unless the super low cracking pressure of Series CKD is absolutely a requirement. Flow performance of 1/4″ size exceeds the recommended flow rates for fractional size tubing. • Very compact; slim design — not much larger diameter than corresponding pipe size. |

FE thermoplastic Check Valves help you stop unwanted reverse flow with an automatic bubble-tight seal.

FE thermoplastic Check Valves help you stop unwanted reverse flow with an automatic bubble-tight seal.

Series CKS:

Series CKS: The drawback, of course, is that it is dependent on some reverse pressure for sealing assistance, and in low flow applications requires gravity to seal (install with flow direction “up”). But please note that when used for liquids with a high specific gravity, the disk may “float,” so it is therefore recommended to install with flow direction “down” with those types of liquids.

The drawback, of course, is that it is dependent on some reverse pressure for sealing assistance, and in low flow applications requires gravity to seal (install with flow direction “up”). But please note that when used for liquids with a high specific gravity, the disk may “float,” so it is therefore recommended to install with flow direction “down” with those types of liquids.