RVDT/RVDTM

PTFE Diaphragm Relief, By-Pass, Anti-Siphon and Back Pressure Valves

Series RVDT & RVDTM

Thermoplastic or Metal Valves for Smooth, Sensitive Operation and the Ultimate in Corrosion Resistance

…with No Wetted Elastomers!

Applications:

One valve design functions as an all-purpose backpressure valve in many applications:

- Relief: protects systems and equipment from over-pressure/pressure surges.

- By-Pass: prevents pumps from “dead heading”.

- Back-Pressure Regulator: maintains necessary reverse pressure in closed loop systems.

- Back-Pressure Valve: enhance pump performance by maintaining backpressure on the pump outlet

- Anti-Siphon: used on the outlet of a pump wherever gravity or other downstream conditions may create negative pressure (siphon) and drain a tank. The valve is pre-set to open under pump pressure, but closes bubble-tight when the pump is shut off. Because of the design of the RVDT, this valve actually closes more tightly when unwanted siphon occurs.

Plastic Body Materials, Sizes & Features:

- Geon® PVC and Kynar® PVDF body materials in 1/4″, 1/2″, 3/4″, 1″, 1 1/2″, 2″, 3″ and 4″ sizes.

- Natural Polypropylene and Corzan®CPVC body materials in 1/4″ – 2″ sizes.

- PTFE body material offered in 1/4″ – 1″ sizes.

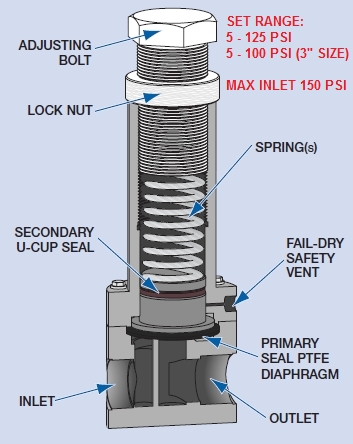

- Relief setting is infinitely adjustable from 5 psi to 125 psi; 5 to 100 psi on 3″ and 4″ sizes.

- Maximum inlet pressure is 150 psi.

- Diaphragm material is PTFE for all sizes and body materials, and is excellent for use with highly aggressive liquids…provides the ultimate in contamination-free sealing.

- Rugged thermoplastic construction is ideal for a broad range of industrial applications.

- Large diaphragm area delivers more sensitivity and less pressure drop under flow conditions.

- Non-wetted u-cup seal provides a second isolation of the control spring; design includes patented Fail-Dry vent, a safety feature that provides visual warning of seal malfunction. This permits the valve to continue operation until a scheduled maintenance can be planned thereby avoiding a costly shutdown. Fail-Dry connection on Series RVDT is 1/8″ FNPT.

- Non-leaching feature of fluoropolymer diaphragm makes it ideal for use with ultra-pure water and concentrated etchants, as in the semiconductor industry.

Metal Body Materials, Sizes & Features:

- 316L Stainless Steel body offered in 1/2″, 3/4″, and 1″ sizes. For other grades/metals, please consult factory.

- Relief setting is infinitely adjustable from 5 psi to 125 psi.

- Maximum inlet pressure is 150 psi at 75º F. With PVC spring housing, pressure is derated accordingly at higher temperatures. Alternate spring housing materials are available; please consult factory.

- All other specifications are identical to plastic body valves.

Both plastic and metal body designs feature the same external and internal dimensions, providing the ultimate flow performance. Please click here for a photographic comparison of the inner workings of Series RVDT vs. competitor’s BPV: Not all Backpressure Valves are Created Equal!

Materials, Manufacturing Process & Quality Assurance:

Materials used in addition to the body include PTFE wetted diaphragm energized by a non-wetted FKM diaphragm. Spring housing (not wetted) is PVC. Springs (not in wetted area) are zinc-plated steel, external fasteners are stainless steel. Optional Xylan coated springs and fasteners available; consult factory. Lock nut and adjusting screw are HDPE on 1/4″ – 1″ and 3″ sizes. Lock nut and adjusting screw are stainless steel on 1½” and 2″ sizes. If your environment is incompatible with any of the external materials, or you are interested in some other type of body material, options are available on quantity or special orders.

Valve bodies are machined on state-of-the-art CNC lathes and machining centers. Parts are individually inspected prior to assembly. Valves are hand assembled, then inspected. Assembled valves are 100% individually tested (while pressurized) prior to shipment. All operations performed in our plant in Cedar Grove, NJ.

Optional Class 100 cleanroom cleaning and packing including wipe, rinse, Triton flush, nitrogen flush, DI rinse, nitrogen purge/dry, flourescent inspection, capping & 6 mil PE bag and heat seal available upon request. Performed at a certified remote location; priced per valve.

Larger valve shown in photo has a Natural Polypropylene body. Spring housing (completely non-wetted) is Geon PVC, but can be constructed of the wetted body material for a slightly higher cost. Cutaway example in photo is an all-PVC valve.

The standard valves are precision machined from the highest quality brand thermoplastic bar stock with female NPT connections. 1/2″ sizes in Geon PVC, Corzan CPVC, Natural Polypro & Kynar PVDF, as well as 1″ sizes in Geon PVC, Natural Polypro & Kynar PVDF are molded with a choice of FNPT or socket connections. Spigot connections & flare fittings are also available on all sizes. For orders of 25 or more valves, connections can be provided with male threads, sockets, unions, etc. Please consult our Technical Group for more information, (973)256-3000.

Mounting

Mounting

1/2″ size in PVC, CPVC, Natural Polypro & Kynar PVDF, as well as 1″ sizes in PVC, Natural Polypro & Kynar PVDF have integral mounting lugs on the base of the body, as shown at right. This is in addition to mounting holes in the base. These sizes and materials can be ordered optionally without the mounting lugs if desired.

All other sizes & materials have threaded mounting holes in the base.

Gauge Ports & Fail Dry Port

1/2″ size in PVC, CPVC, Natural Polypro & Kynar PVDF have opposing 1/8″ NPT gauge ports on the side of the body, on the same plane as the piping connections, as shown at right. 1″ size in PVC, Natural Polypro & Kynar PVDF have opposing 1/4″ NPT gauge ports on the side of the body, on the same plane as the piping connections, as shown at right. The gauge ports are not tapped unless so ordered; incurs small charge. On the standard body, the untapped port has no effect on flow or performance. Gauge ports are not readily available on other size/material combinations; please consult factory for alternatives.

The threaded port above the piping connection is the patented Fail-Dry early warning vent. Fail-Dry is standard on all sizes and materials. Fail-Dry connection is 1/8″ NPT except RVDT300 the connection is 1/4″ NPT.

PTFE Bodies

When this valve is specified PTFE body in 1/4″, 1/2″ or 3/4″ sizes, the base of the valve includes an 18-8 stainless steel reinforcement ring. This reinforcement is used to ensure proper torque on the fasteners, due to the propensity of PTFE to “cold flow” in these sizes.

PTFE valves are offered in NPT, BSP, flare, and custom fittings.

3″ Body Style

Offered in PVC or PVDF, the high volume 3″ and 4″ sizes are visually different, but internally the valve is identical to the smaller sizes; it provides the same PTFE diaphragm sealing but with slightly lower set pressure capability (5 – 100 PSI).

Each of the 3″ RVDT valves are precision machined on state-of-the art CNC machines. They are then individually compression fabricated and assembled by hand, and individually tested under pressure. The design minimizes production waste and facilitates an ultra-heavy duty connection thickness, offered in NPT, socket, BSP, JIS, DIN, and custom fittings.

Dimensions ¼” – 2″:

For 3″ dimensions, see below

Dimensions 3″:

Part Numbers:

| RVDT / RVDTM PART NUMBERS | ||||||

|---|---|---|---|---|---|---|

| Pipe Size | PVC* | CPVC* | Natural Polypro |

PTFE | PVDF | Stainless Steel* |

| ¼” | RVDT025T-PV | RVDT025T-CP | RVDT025T-PP | RVDT025T-TF | RVDT025T-PF | |

| ½” | RVDTM050T-PV | RVDTM050T-CP | RVDTM050T-PP | RVDT050T-TF | RVDTM050T-PF | RVDT050T-SS |

| ¾” | RVDT075T-PV | RVDT075T-CP | RVDT075T-PP | RVDT075T-TF | RVDT075T-PF | RVDT075T-SS |

| 1″ | RVDTM100T-PV | RVDTM100T-CP | RVDTM100T-PP | RVDT100T-TF | RVDTM100T-PF | RVDT100T-SS |

| 1-½” | RVDT150T-PV | RVDT150T-CP | RVDT150T-PP | consult factory | RVDT150T-PF | |

| 2″ | RVDT200T-PV | RVDT200T-CP | RVDT200T-PP | consult factory | RVDT200T-PF | |

| 3″ | RVDT300T-PV | |||||

Connections: NPT threads standard.

For Socket, add “S” prior to the material suffix hyphen. For example, RVDT075TS-PV.

For flanges, add FL, e.g. RVDT075TFL-PV.

For flare, add FR, e.g. RVDT075TFR-PP.

For spigots, add SP. For metric spigots, change size to mm equivalent, e.g. RVDT075TSP-PF becomes RVDT25TSP-PF.

Note Concerning “V” Part Numbers: Previous part numbering of the RVDT Series had a second “V” in place of the second “T” — for example, RVDT075T-PV was formerly RVDT075V-PV. The second “V” indicated the backing seal material, Viton, rather than the primary seal material, PTFE. In 2009 the nomenclature was changed to eliminate confusion. The valves are the same.

*RVDT/RVDTM in PVC, CPVC and Stainless Steel body materials meet NSF-61 and ANSI-372 per the material suppliers.

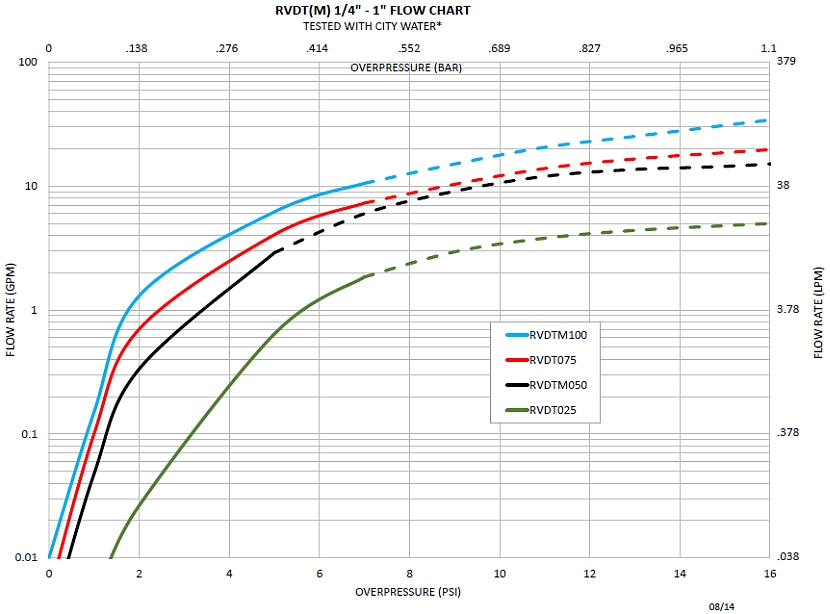

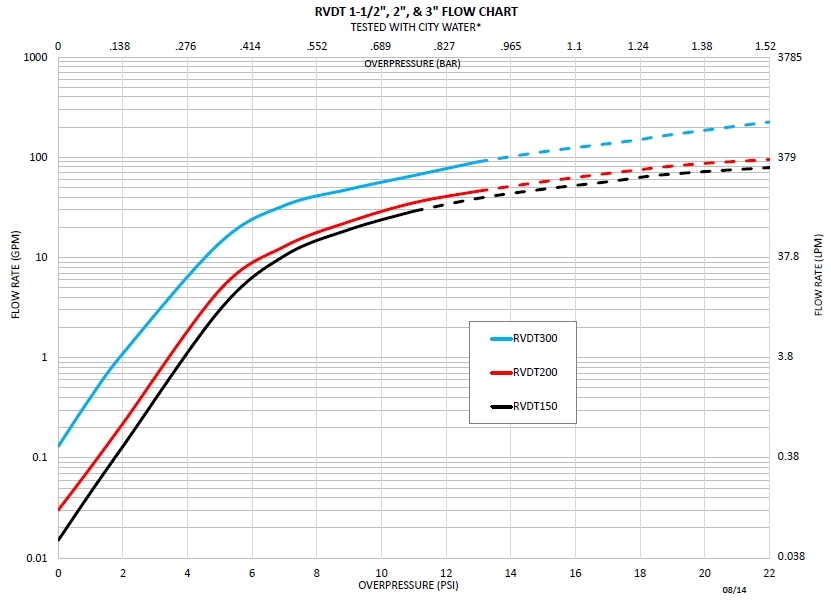

Flow Reference Charts:

NOTE: Flow performance tested with city water under laboratory conditions; your results may vary. Solid lines represent recommended flow range for that pipe size.

* Valves tested using water under laboratory conditions; field conditions may vary.

For comparison flow curves of Series RVDT vs. competitor’s BPV valve, please click here.

Optional Connections:

Standard valves shipped with NPT threaded connections. BSP threads, sockets, metric sockets, spigots, flanges, flare and other connections available; consult factory. Stainless steel body RVDT at right shown with optional stainless steel flange fittings.

Standard valves shipped with NPT threaded connections. BSP threads, sockets, metric sockets, spigots, flanges, flare and other connections available; consult factory. Stainless steel body RVDT at right shown with optional stainless steel flange fittings.

Mounting

Mounting